The battery board manages charging, power, and safety for drones, robots, and RC toys. It works with 2 to 4 cell batteries.

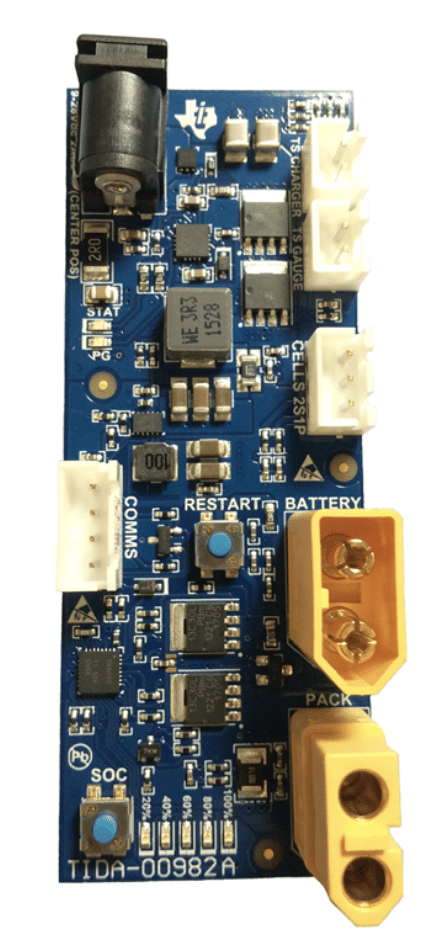

The TIDA-00982 is a battery management system (BMS) reference design from Texas Instruments, tailored for 2S1P Li-Poly battery packs used in non-military drones, robots, and RC projects. It brings together essential battery functions—charging, fuel gauging, protection, and balancing—on a single compact PCB. It includes onboard State of Charge (SOC) monitoring, SMBUS communication, and a configurable buck regulator that provides either 3.3 V or 5 V at 500 mA, suitable for powering microcontrollers or external components. This design supports 2S by default but can be adjusted for 3S or 4S systems with minor changes. It is compatible with drones in the 200 mm and 250 mm class, as well as RC cars, helicopters, and robotic systems.

This board is designed to handle up to 30 A peak current and 15 A continuous current, making it suitable for applications that demand high power, such as rapid motor acceleration. It was tested with a 2S1P 1.3-Ah battery at a 25 C discharge rate. The charger on the board is preset to 1.3 A (1 C), but can be increased to 4 A to support larger batteries up to 4 Ah, requiring only a simple adjustment to the charging current. The design also supports both the bq4050 CEDV gauge and the bq40Z50 Impedance Track gauge, which are pin-to-pin compatible, allowing users to switch between algorithms based on application needs.

By combining all the essential BMS functions into one board, TIDA-00982 significantly simplifies the design process. Engineers do not have to source or configure separate modules for gauging, charging, balancing, and protection. This compact integration also reduces board size and wiring complexity, which is particularly useful for small-scale drone and RC platforms. The ability to accurately gauge battery status during high discharge events—up to 25–50 C—gives it a major advantage over other designs that may fail under such load.

The board’s flexible architecture means it can support a range of battery sizes and configurations with minimal changes. The buck regulator allows easy voltage adjustments for powering external circuits. Additionally, the use of standard, low-cost connectors ensures compatibility with off-the-shelf components, reducing cost and simplifying assembly.

For developers and engineers, the design offers clear benefits. It enables rapid prototyping and testing of smart battery features without requiring deep expertise in battery electronics. Its high-current handling ensures stable performance under demanding conditions, such as drone take-off or robotic movement. The onboard fuel gauging, protection, and SOC indicators help monitor battery health and performance in real time, contributing to longer battery life and safer operation.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.