AI-powered Robot, turning cockroaches into cyborgs, for search and rescue missions.

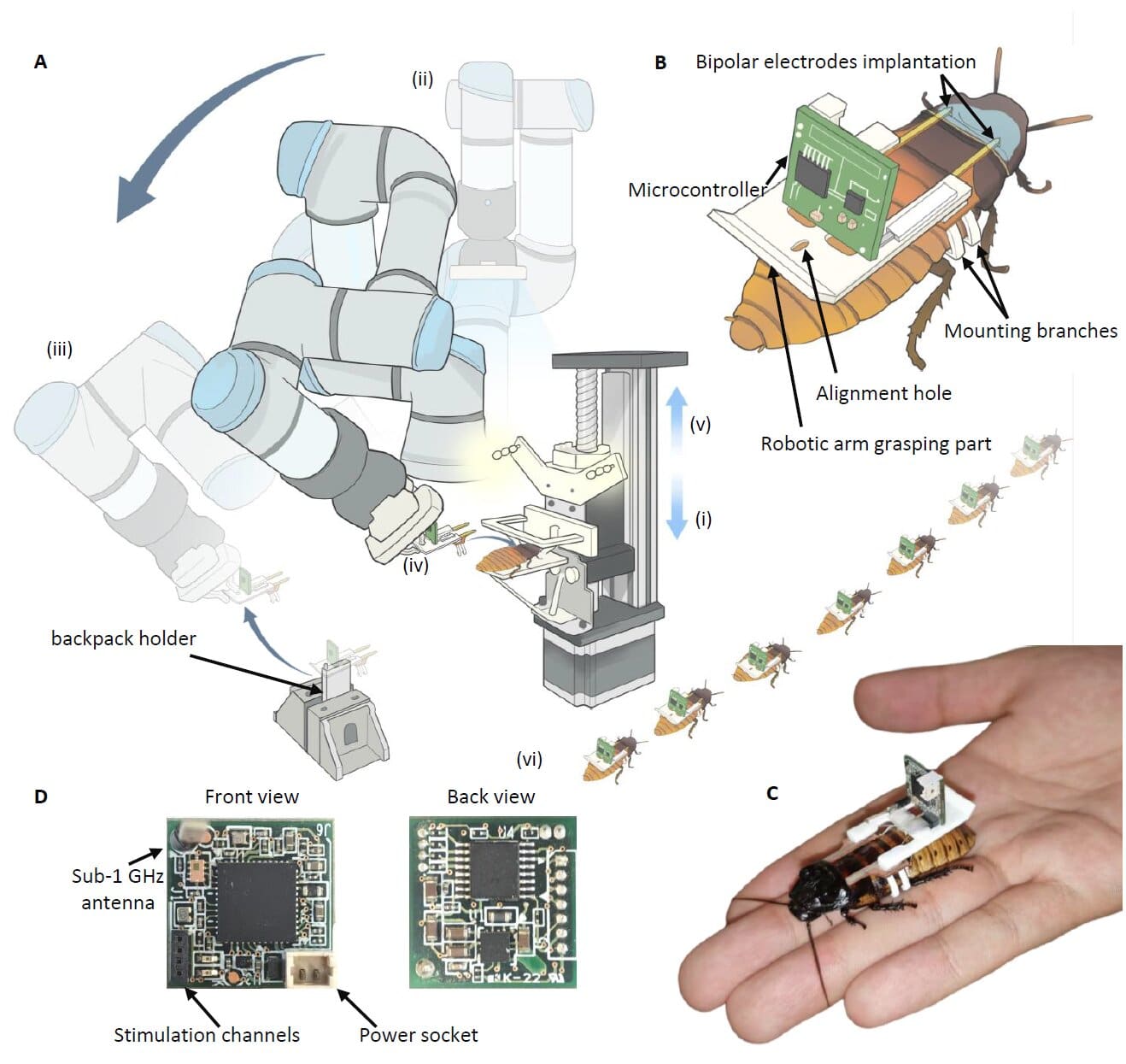

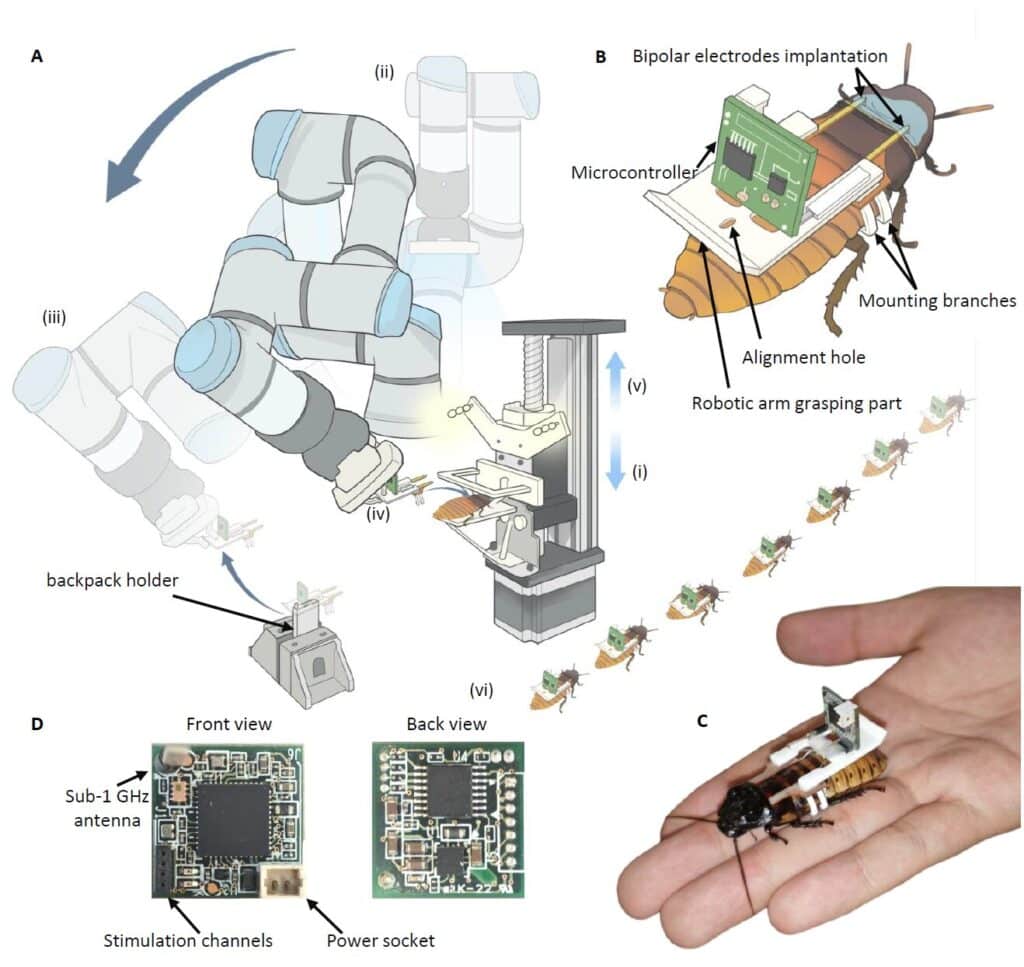

Researchers at Nanyang Technological University (NTU) Singapore have developed a robotic system capable of autonomously assembling cyborg insects. The innovation dramatically reduces the time required to prepare insect-hybrid robots, paving the way for their broader deployment in disaster response and complex terrain navigation.

The automated system equips Madagascar hissing cockroaches with lightweight electronic backpacks that enable remote-controlled movement through neural stimulation. Each cyborg insect is assembled in just over a minute, which is 60 times faster than traditional manual methods that require skilled operators and over an hour per insect. In early tests, four cyborgs were completed in under eight minutes.

These insect-hybrids retain their natural mobility while being guided by electrodes implanted on their backs. The AI-powered system identifies optimal points for electrode placement using computer vision and custom algorithms. The latest backpack design also uses 25% less voltage than previous models, improving power efficiency and reducing risks to the insects.

By giving gentle electrical simulation, the cyborg moves its limb. In test environments, the cyborg cockroaches displayed precise manoeuvrability by being able to control its speed and making it take 70 degree turns. A group of four insects successfully covered more than 80% of an obstacle-filled space in under 11 minutes.

Earlier this year, a small team of these manually assembled cyborg insects was deployed in Myanmar following a deadly 7.7-magnitude earthquake. The mission marked the first real-world use of insect-hybrid robots in humanitarian search and rescue operations.

Researchers now aim to scale production of these bio-hybrid systems to support time-sensitive missions, such as locating survivors in collapsed buildings or inspecting hard-to-reach infrastructure. Though still in the prototype stage, NTU’s assembly line lays the foundation for mass-producing cyborg insects for field use. Plans are underway to enhance the system and explore industrial partnerships to bring the technology to operational maturity.