What if 90% of sensing losses simply disappeared? This isolated current sensor cuts heat, removes heatsinks, and frees 95% board space in high-current designs.

Allegro MicroSystems has introduced the ACS37200, a galvanically isolated current sensor designed to reduce power loss and improve efficiency in high-current systems. The main issue in high-current designs is resistance. In a 100A system using a 0.5 mΩ shunt resistor, about 5W of power is lost as heat. This wasted energy often requires large heatsinks and extra board space.

The current sensor uses a 50 µΩ conductor, cutting power loss to about 0.5W. That is a 90% reduction in wasted power. More energy is delivered to the load instead of being lost as heat. This can help extend EV range and lower energy use in data centers.

Lower resistance also supports higher power density. As systems in HEV/EV platforms, industrial automation, AI data centers, and solar inverters become smaller and more powerful, managing heat becomes harder. By reducing heat at the sensing stage, designers can simplify thermal management and reduce overall system size.

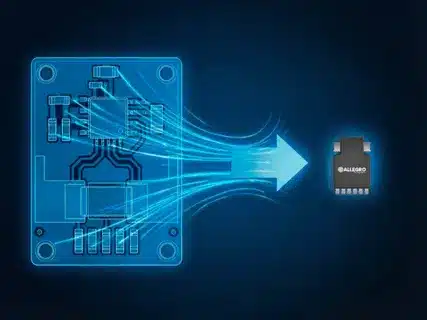

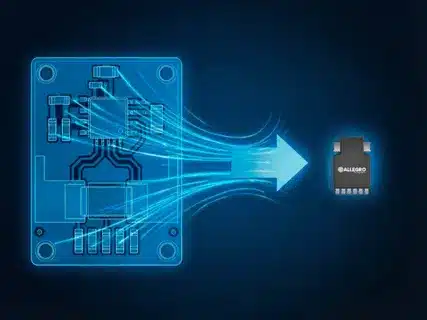

The ACS37200 also improves space efficiency. Allegro’s earlier integrated sensor, the ACS772, reduced size compared to discrete shunt solutions. The new device goes further. In its 100 mm² PSOF package, it is nearly 70% smaller than the ACS772’s CB package. Compared to a traditional shunt-based design, it offers a footprint about 20 times smaller, cutting board space by roughly 95%.

Because it generates very little heat, bulky heatsinks are not required. Its integrated isolation removes the need for external isolation components. Together, these changes help engineers build compact, efficient, and high-current power systems without the limits of conventional shunt resistors.

“Our customers consistently tell us that power is a major bottleneck. Systems need to monitor, convert and deliver more power than ever before in the same or even smaller form factors,” said Matt Hein, Business Line Director of Current Sensors at Allegro MicroSystems. “By drastically cutting power loss and offering a 95% reduction in footprint, we are giving our customers more design freedom, higher power density, and a faster path to building smaller, more efficient systems for the future of e-Mobility, industrial automation, and clean energy.”