Hyderabad-based deep-tech startup Xbattery is developing intelligent, secure BMS solutions to power India’s clean energy and electric mobility shift.

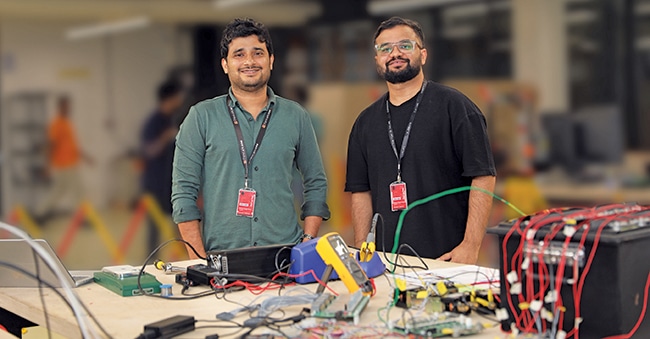

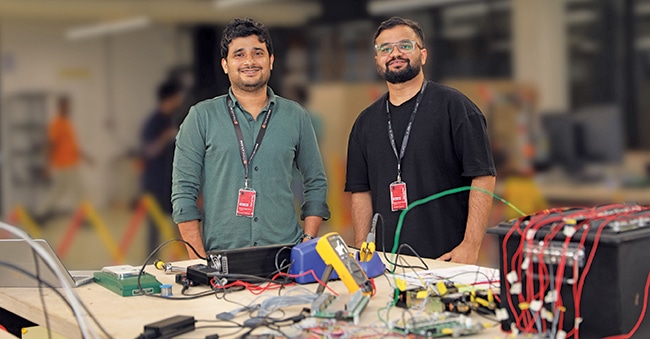

Founded in August 2024 by Satish Reddy and Sonu Mishra, Xbattery Energy Pvt Ltd is an emerging deep-tech firm focused on designing indigenous battery management systems (BMS) for electric vehicles and stationary energy storage.

The company’s flagship product, BharatBMS, is a high-tech printed circuit board (PCB) entirely designed and manufactured in-house. It functions as the central electronic control unit within battery packs, ensuring intelligent and efficient battery management. BharatBMS is available in the market, priced between ₹2000 and ₹25,000, depending on the configuration. The cost varies based on voltage requirements—lower for scooters and higher for trucks or larger vehicles.

Another key offering from Xbattery is a 5kWh home energy storage system, developed as a modern replacement for traditional inverter-based backup systems. This lithium-based system incorporates the BharatBMS and is assembled in-house using imported battery cells. It is expected to launch in the market within the next three months.

Satish highlights BharatBMS’s configurability and broad compatibility with various voltages and chemistries, including LFP and NMC, making it suitable for everything from two-wheelers to telecom towers and residential systems.

“The platform allows rapid deployment through prevalidated hardware and software stacks, cutting time to market and development costs. Its modular architecture enables scalable configurations ideal for large systems like electric buses. With its chemistry-agnostic design, BharatBMS is future-ready, compatible with sodium-ion batteries and able to replace imported BMS solutions with ease,” adds Satish.

BharatBMS supports a wide range of communication protocols, including CAN, RS-485, SPI, and CAN UDS, enabling smooth communication with vehicle systems, inverters, and third-party fleet management software.

Satish explains that the ‘X’ in Xbattery stands for versatility and exploration, much like in mathematics, where ‘X’ represents the unknown. It reflects the startup’s spirit of innovation and adaptability. The term ‘battery’ suggests a dynamic, evolving system attuned to the changing demands of energy and mobility.

The startup serves two main customer segments: automotive OEMs, including manufacturers of electric cars, buses, and trucks, and system integrators specialising in stationary energy storage. These integrators use Xbattery’s BMS to build large-scale battery packs for residential, commercial, and grid-level applications.

The team claims that nearly all aspects of the product development process, testing, programming, assembly, and design have been built in-house. Specialised tools such as thermal chambers, battery welders, electronic loads, and programmable chargers are critical to its workflow. While some mechanical parts, like metal cases, are fabricated externally, core processes, PCB design, firmware, thermal analysis, and assembly are handled at the company’s Hyderabad facility. For PCB fabrication and testing, Xbattery collaborates with T-Works, a government-supported initiative offering access to necessary equipment.

Satish notes, “We are still pre-revenue but have already rolled out pilots for internal use and select customers. We have secured a 225-unit order from a real estate developer and are in talks with several OEMs for bulk deals. Commercialisation should begin in three to six months. So far, we have been backed by angel investors and are preparing for a venture capital raise.”

Xbattery has also filed patents covering core BMS technology, signalling its commitment to innovation and intellectual property protection. The company is headquartered in Hyderabad and currently employs around 23 people.

On the customer support side, BharatBMS comes with a five-year warranty and includes technical support post-integration. Battery packs assembled by the company come with a ten-year warranty on the cells and optional annual maintenance contracts. These offer peace of mind to customers, although maintenance needs are minimal due to the absence of moving parts.

One of the fundamental challenges identified by the team is the lack of a robust ecosystem to support BMS development in India.

“Testing BMS demands specialised equipment and battery packs, which are often unavailable in India. Importing them delays timelines due to customs and regulations. Even small batches of test electronics take time. Chip sourcing is another challenge, with 20% still coming from Europe. On top of that, deep-tech startups face a shortfall in financial and institutional support. Government grants exist but are difficult to access and often inadequate,” Satish concludes.