Researchers at VCU and Princeton have developed a sustainable method to create semiconductor quantum dots using engineered proteins in water at room temperature—eliminating the need for toxic solvents and high-energy processes.

In a breakthrough that could redefine how semiconductors are made, researchers have developed a sustainable method to produce quantum dots—tiny semiconducting particles used in electronics and displays—without the high energy costs or toxic solvents typically involved in the process. Semiconductors are at the heart of modern electronics, from smartphones and TVs to solar cells and sensors. However, conventional fabrication methods rely on hazardous chemicals and require extreme conditions, such as high temperatures and pressures, which contribute to environmental degradation and high production costs.

Now, a team led by Dr. Leah Spangler, assistant professor at Virginia Commonwealth University’s College of Engineering, in collaboration with Dr. Michael Hecht, chemistry professor at Princeton University, has introduced a game-changing technique. Their method uses engineered, or de novo, proteins to guide the formation of semiconductor quantum dots—entirely in water, at room temperature.

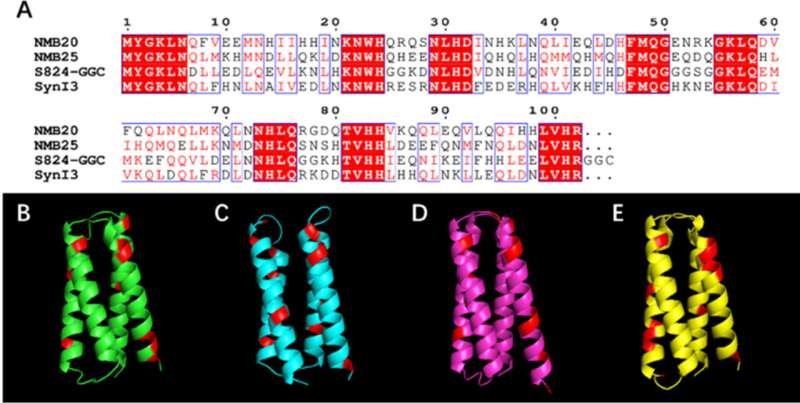

Published in ACS Central Science, their study titled “De Novo Proteins Template the Formation of Semiconductor Quantum Dots” highlights how synthetic proteins can be used as nanoscale templates, controlling the growth and properties of the materials they help assemble.“Unlike natural proteins harvested from organisms, de novo proteins are designed from scratch for specific functions,” explained Spangler. “This opens up entirely new possibilities for precision control over material synthesis, potentially transforming how we approach green chemistry and nanomaterials.”

The process mimics biomineralization—a phenomenon where organisms naturally form complex mineral structures—but takes it a step further by designing proteins to orchestrate material growth with molecular-level accuracy.This is the first known instance of using designed proteins for the controlled synthesis of quantum dots, suggesting that custom-built proteins could soon serve as eco-friendly ‘nano-factories’ for semiconductor production.

With global demand for semiconductors surging and environmental regulations tightening, the implications are vast. This technique could not only reduce the carbon footprint of electronics manufacturing but also inspire a new class of biomolecular tools tailored for sustainable materials science.