We currently use a lot of ammonia to produce fertilizer, refrigerants, and other chemicals, and unfortunately rely heavily on an energy-intensive process developed in the 19th century – the Haber-Bosch process – to make it in large quantities.

There are many efforts at play to figure out greener ways to produce ammonia, but this new one out of the University of Sydney might be the most electrifying of the lot: researchers there are using human-made lightning to produce the compound in gaseous form from air.

This new method doesn’t require a lot of energy, nor does it need any fossil fuels or expensive raw material, and it has a significantly lower environmental impact – the latter being hugely important when you consider the scales at which ammonia is produced and used worldwide.

Back to the fun stuff: human-made lightning! What’s happening at the start of this process is that electricity is being used to excite nitrogen and oxygen molecules directly from the air. This isn’t just heating them up; it’s about giving them energy to break their strong bonds and become more reactive in a plasma phase.

PJ Cullen

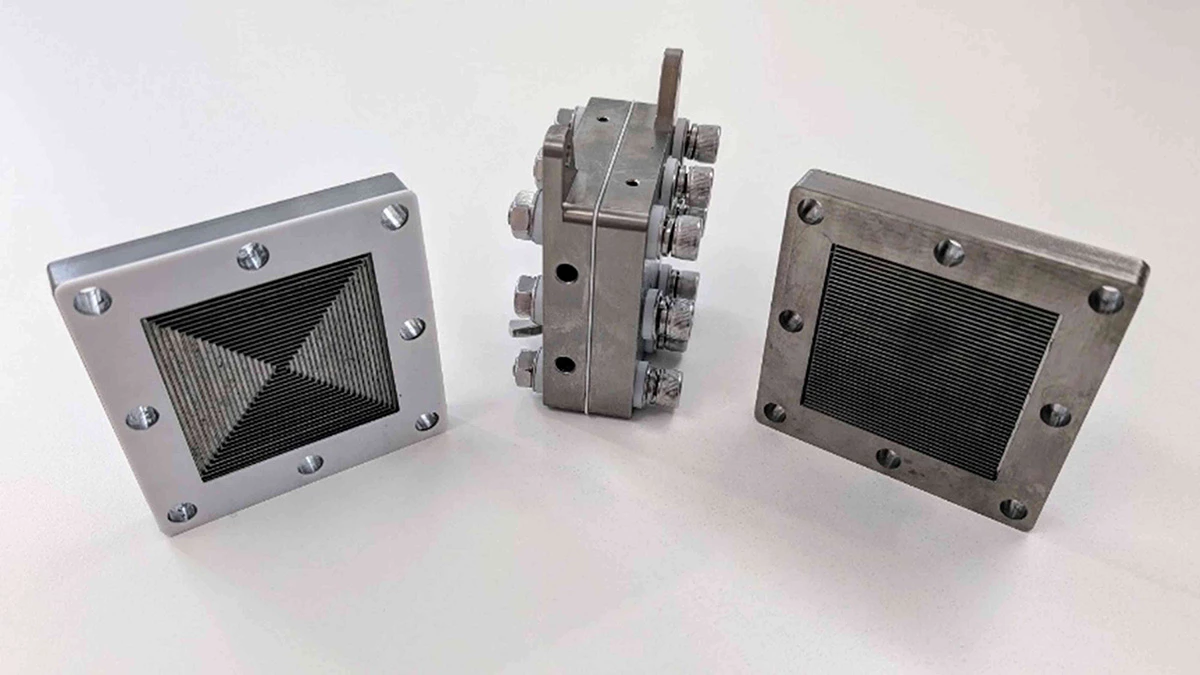

That’s similar to a lightning strike, where lightning strips electrons from air molecules to create a conductive plasma channel in the air. The activated nitrogen oxide (NOx) molecules from that plasma treatment are then passed into a special membrane-based electrolyzer.

Inside this electrolyzer, there’s a unique catalyst called highly defective Fe2O3 nanoparticles on copper. The catalyst has special active sites called “oxygen vacancies” – these are like tiny gaps or imperfections on its surface that make it very reactive and provide spots for the NOx molecules to attach.

When the NOx molecules come into contact with this catalyst, they undergo an electrochemical reduction reaction. In essence, hydrogen atoms are successively added to the nitrogen-containing species. This process largely follows an optimal chemical route known as the “NHO pathway.”

The catalyst significantly lowers the energy required for these key steps where hydrogen is added, making the conversion to ammonia much easier and more efficient than using just copper.

The result is the direct production of gaseous ammonia (NH3). Because the ammonia is produced as a gas, it can be easily separated and collected, avoiding issues with dissolving in liquids and subsequent separation steps – making it a lot less demanding than the Haber-Bosch process.

PJ Cullen

“Currently, generating ammonia requires centralized production and long-distance transportation of the product,” lead researcher Professor PJ Cullen said. “We need a low-cost, decentralized and scalable ‘green ammonia’.” Given that this method doesn’t require high temperatures and pressures, or even high-purity nitrogen and hydrogen, it appears the chemical engineering team might have succeeded.

The group published a paper on this method in the AngewandteChemie International Edition journal in April. “To create a more complete solution to a sustainable ammonia productive, we need to push the energy efficiency of the electrolyzer component,” Professor Cullen said. The goal there would be to make this method more energy efficient that the Haber-Bosch process.

Alongside the Sydney team’s work, researchers elsewhere in the world are trying to greenify ammonia production in different ways, in the hopes of reducing its enormous 1% contribution of all greenhouse gas emissions on the planet. A group at MIT is looking into ‘brewing’ ammonia beneath the Earth’s surface, and chemists at the University of New South Wales are throwing AI at the problem of identifying a suitable catalyst out of 8,000 options. And last year, researchers at Stanford University developed a portable device that can produce ammonia anywhere at room temperature.

Source: University of Sydney