Researchers at POSTECH have developed a dry adhesive using shape memory polymers that enables precise pick-and-place of micro-LEDs and everyday materials—without glue or residue, this could transform display manufacturing and smart assembly systems.

A research team from Pohang University of Science and Technology (POSTECH) has introduced a dry adhesive technology that enables easy attachment and detachment of a wide range of materials—from microscale electronic components to everyday items like paper or fabric. This work was rwas led by Professor Seok Kim in collaboration with scientists from POSTECH, Gachon University, Chonbuk National University, and the University of Connecticut.

The core motivation for the research came from the manufacturing challenges of micro-LEDs, a next-generation display technology known for its brightness, flexibility, and durability. Micro-LED chips are incredibly tiny—smaller than a human hair—and transferring them to display panels with accuracy has been a major obstacle. Traditional methods using wet adhesives or transfer films often result in poor alignment, contamination, and complex steps.

The researchers tackled a known issue in surface science called the “adhesion paradox,” where strong atomic-level adhesion is expected in theory, but in practice, surface roughness prevents strong contact. The team flipped this limitation into an advantage.

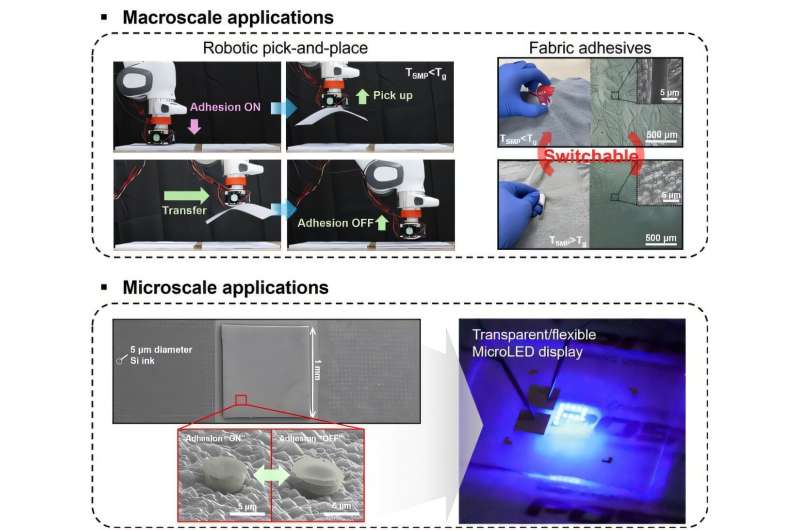

Their innovation uses shape memory polymers (SMPs) embedded with nano-sized tips. At normal temperatures, the material’s rough surface leads to low stickiness. But when heated and pressed, the surface smooths out—similar to ironing clothes—allowing it to strongly adhere to objects. Upon reheating, the material regains its rough texture, releasing the object effortlessly.

This reversible bonding mechanism delivers powerful adhesion (over 15 atmospheres) when engaged and nearly zero force when disengaged. In demonstrations, micro-LEDs were picked and placed precisely by a robotic arm, and the adhesive worked just as well on soft materials like paper or fabric.

“This technology allows ultra-precise handling of delicate components without sticky residues,” said Professor Seok Kim. The researchers believe it can revolutionize industries like display manufacturing and semiconductor assembly, especially as smart manufacturing continues to evolve.